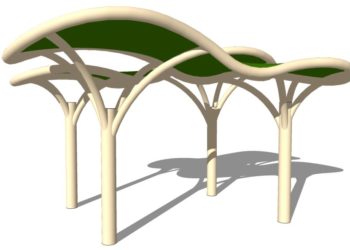

A tensioned membrane structure is an incredibly versatile and cost-effective alternative to traditional forms of architecture. They help architects and builders overcome a wide range of functional and aesthetic challenges – from improving energy efficiency to spanning long distances with minimal support to transforming ordinary properties into iconic ones.

As semi-permanent or permanent buildings and canopies, it’s important to understand that the design-build process for tensioned membrane structures is less like that of a temporary tent (no matter how high-quality that tent may be) and more like a traditional construction project. In other words, a tensioned membrane structure won’t “pop up” overnight, but it will last for years and years to come.

A Sample Timeline for a Tensioned Membrane Structure

The time it takes to build a tensioned membrane structure depends upon the material, size, and scope of the project. Most often, it takes between five and twelve months to complete the project.

Here’s a sample of what you could expect from a 22-week timeline for a medium-sized project:

- (3) Weeks for 3D design drawings from time of approved contract terms and receipt of deposit

- (3) Weeks for engineering analysis and calculations from time of design approval

- (3) Weeks for stamped engineering report and drawings after completion of engineering analysis

- (2) Weeks for field measurements from time of footing completion

- (2) Weeks for shop drawings after field measurements are surveyed

- (2) Weeks to order and receive materials after completion of shop drawings

- (4) Weeks to fabricate frame and fabric membrane after receipt of materials

- (1) Week to paint frame after its fabrication is complete

- (2) Weeks to deliver and install frame and fabric membrane

Examples of Longer Timelines

There are many reasons a tensioned membrane structure project’s timeline may be significantly longer. All of these circumstances (but not limited to) can contribute to additional lead times:

- Large projects (over 4,000 sq. ft.)

- Client’s desire to negotiate contract terms

- Client’s approval time of design drawings

- Possible design revisions due to engineering requirements

- Permitting authorities time to review and approve project

- Coordination with schedules of other on-site subcontractors

- Acquisition of specialty materials that are uncommon and not stocked locally

- Delivery to sites outside of the South West Region.

From the initial concept to the final unveiling, the process for creating a tensioned membrane structure requires well-established expertise at every step along the way. At Eide Industries, our team of experts in the Tension Structures division guide you through the entire process to ensure to top levels of service, safety, and quality.

Is a Tensioned Membrane Structure Right for Your Next Project?

In the Tension Structures Division of Eide Industries, we specialize in design, engineering, manufacturing, and installation of structurally complex and creatively challenging commercial, government, and prototype design projects. We provide expertise and support for architects, landscape designers, general contractors, and property owners to develop their custom tensile membrane project ideas and construct iconic structures.

Explore the options for your next project. Contact one of our experts today by calling 800-422-6827.